| Availability: | |

|---|---|

| Quantity: | |

SAC305

Sigway

PRODUCT DESCRIPTION

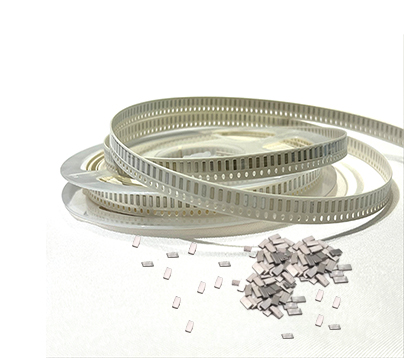

Preformed patches usually have standardized shapes and sizes, and compared to traditional solder wire or solder solder, preformed patches can provide precise solder amounts, improving the accuracy and consistency of the welding. Thereby improving welding quality and efficiency

First of all, the preformed solder block has a high degree of weldability. It is made of high-quality solder alloy material, which can be quickly melted and evenly coated on the welding surface to

ensure the fastness and electrical conductivity of the welding point. Whether it is manual welding or machine welding, preformed solder blocks can provide stable welding results and greatly improve work efficiency.

Secondly, Sigway prefabricated tin sheet is designed to increase the amount of tin locally, which effectively reduces the probability of insufficient tin during welding. This design ensures that the welding area is fully filled, thus improving the welding quality.

In addition, Our company has independently developed a pre formed solder series with reel and roll packaging. All standard soldering alloys are available for selection; Can reduce the need for solder paste overlay, thereby reducing flux splashing: reduce the flux/solder paste ratio in standard solder paste, thereby reducing flux residue.

SAC series is the most commonly used lead-free solder series for electronic soldering, such as SAC305 (Sn96.5Ag3Cu0.5), SAC307 (Sn99Ag0.3Cu0.7), and SAC405 (Sn95.5Ag4Cu0.5). Usually used for reflow soldering, wave soldering, and manual soldering, the melting point is around 217 ℃. Its hardness, tensile strength, yield strength, shear strength, impact strength, and creep strength are higher than those of eutectic Sn63Pb37. The wetting properties are also superior to Sn Cu and Sn Ag solder.

We can customize various sizes/alloys of prefabricated tin sheets. Please feel free to contact us for consultation.

PRODUCT PARAMETER

| Product name | preformed solder block | Brand | Sigway |

| Shape | block | Material | Various tin alloys can be customized |

| Melting Point | 217±2℃ | proportion | 7.5±0.1g/cm3 |

| Specifications | 2.0*1.2*0.4mm | Model | 0805 |

| Lhickness | 0.4MM | place of production | Dongguan, China |

| Unit | roll up | Quantity per roll | 4000 pieces/roll |

PRODUCT FEATURES

Excellent liquidity

Strong tin ability

The solder joint surface is bright and smooth

Strong antioxidant capacity

Good wettability

Bright and smooth surface

high reliability

Various sizes/alloys can be customized

PRODUCT ADVANTAGES

01 High efficiency

Pre tin alloy solder block can quickly automate the placement, automatic brazing and circuit board assembly to improve production efficiency.

02 High accuracy

high accuracy of the patch can ensure the accuracy of electronic components.

03 High reliability

The pre tin alloy solder block can ensure that the electronic components are strong and reduce subsequent maintenance costs.

04 Strong applicability

it is suitable for various types of electronic components and circuit boards, so it can be widely used in various fields and industries, such as electronic assembly, battery assembly, automotive circuit boards, etc.

The 0402 pre formed solder material packaged with SIG WAY reels and scrolls provides a convenient method to increase the amount of solder. Rectangular pre formed solder is inserted into the solder paste, thereby precisely increasing the amount of solder. Standard rectangular pre formed solder can be placed in standard equipment to meet industry standard pick and place requirements.

PRODUCT DESCRIPTION

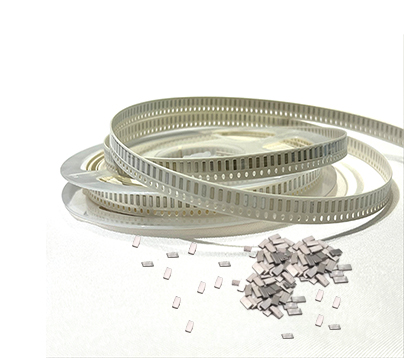

Preformed patches usually have standardized shapes and sizes, and compared to traditional solder wire or solder solder, preformed patches can provide precise solder amounts, improving the accuracy and consistency of the welding. Thereby improving welding quality and efficiency

First of all, the preformed solder block has a high degree of weldability. It is made of high-quality solder alloy material, which can be quickly melted and evenly coated on the welding surface to

ensure the fastness and electrical conductivity of the welding point. Whether it is manual welding or machine welding, preformed solder blocks can provide stable welding results and greatly improve work efficiency.

Secondly, Sigway prefabricated tin sheet is designed to increase the amount of tin locally, which effectively reduces the probability of insufficient tin during welding. This design ensures that the welding area is fully filled, thus improving the welding quality.

In addition, Our company has independently developed a pre formed solder series with reel and roll packaging. All standard soldering alloys are available for selection; Can reduce the need for solder paste overlay, thereby reducing flux splashing: reduce the flux/solder paste ratio in standard solder paste, thereby reducing flux residue.

SAC series is the most commonly used lead-free solder series for electronic soldering, such as SAC305 (Sn96.5Ag3Cu0.5), SAC307 (Sn99Ag0.3Cu0.7), and SAC405 (Sn95.5Ag4Cu0.5). Usually used for reflow soldering, wave soldering, and manual soldering, the melting point is around 217 ℃. Its hardness, tensile strength, yield strength, shear strength, impact strength, and creep strength are higher than those of eutectic Sn63Pb37. The wetting properties are also superior to Sn Cu and Sn Ag solder.

We can customize various sizes/alloys of prefabricated tin sheets. Please feel free to contact us for consultation.

PRODUCT PARAMETER

| Product name | preformed solder block | Brand | Sigway |

| Shape | block | Material | Various tin alloys can be customized |

| Melting Point | 217±2℃ | proportion | 7.5±0.1g/cm3 |

| Specifications | 2.0*1.2*0.4mm | Model | 0805 |

| Lhickness | 0.4MM | place of production | Dongguan, China |

| Unit | roll up | Quantity per roll | 4000 pieces/roll |

PRODUCT FEATURES

Excellent liquidity

Strong tin ability

The solder joint surface is bright and smooth

Strong antioxidant capacity

Good wettability

Bright and smooth surface

high reliability

Various sizes/alloys can be customized

PRODUCT ADVANTAGES

01 High efficiency

Pre tin alloy solder block can quickly automate the placement, automatic brazing and circuit board assembly to improve production efficiency.

02 High accuracy

high accuracy of the patch can ensure the accuracy of electronic components.

03 High reliability

The pre tin alloy solder block can ensure that the electronic components are strong and reduce subsequent maintenance costs.

04 Strong applicability

it is suitable for various types of electronic components and circuit boards, so it can be widely used in various fields and industries, such as electronic assembly, battery assembly, automotive circuit boards, etc.

The 0402 pre formed solder material packaged with SIG WAY reels and scrolls provides a convenient method to increase the amount of solder. Rectangular pre formed solder is inserted into the solder paste, thereby precisely increasing the amount of solder. Standard rectangular pre formed solder can be placed in standard equipment to meet industry standard pick and place requirements.

Low-temperature lead-free solder wires have emerged as a game-changer in the manufacturing industry, especially for acoustic products. These innovative solder wires offer several benefits that make them an ideal choice for various applications. In this article, we will explore the advantages of usin

Power plug terminal soldering is a critical process in the manufacturing of electronic devices. To ensure a reliable and long-lasting connection, it is crucial to use the right solder wire. Nickel-plated lead-free solder wire has emerged as an ideal choice for this application due to its numerous be

Lead-free solder bars have emerged as a crucial solution for meeting the evolving demands of the power and automotive industries. With the increasing concern over the harmful effects of lead, these solder bars offer numerous advantages in terms of environmental sustainability, regulatory compliance,

In the rapidly evolving world of electronics, the hazards associated with lead have become a growing concern. With increased awareness of the negative effects of lead on human health and the environment, manufacturers are seeking alternative materials that provide the same level of performance witho

Stainless Steel Solder Wires for Welding Stainless Steel Tubes: A Comprehensive GuideWelding stainless steel tubes requires precision and expertise to ensure the integrity and durability of the final product. One crucial aspect of this process is choosing the right solder wires. In this article, we

When it comes to quality tin plating and soldering, choosing the right solder bar manufacturer is crucial. The selection process, however, can be overwhelming with so many options available. In this article, we will discuss the factors to consider when choosing a solder bar manufacturer and the key