| Availability: | |

|---|---|

| Quantity: | |

Product Introduction

With the highest precision and efficiency, the Sn60Pb40 solder rod delivers superior performance to ensure a seamless welding experience.

Our Sn60Pb40 electrode is made of the highest quality materials and has a smooth surface. When melted, the surface of the liquid takes on a mirror-like luster.

One of the outstanding features of our Sn60Pb40 solder bars is their excellent fluidity and excellent wettability. This ensures easy application and impeccable adhesion, allowing for seamless welded connections.

During usage, the solder strip produces minimal slag, has excellent flowability, and exhibits good wetting properties, resulting in highly reliable solder joints. It remains bright and intact without any collapses, making it suitable for high-quality wave soldering in various applications. It can also be used for selective wave soldering and manual dip furnace welding.

Basic Info.

Product name | 60a Lead solder bar | Brand | singway |

Model NO. | 6040 | Material | Sn60Pb40 |

Shape | bar | Melting Point | 183±2℃ |

Individual strip weight | About 0.72kg/ piece | Packaging | 20kg/box |

| Product use | All kinds of wave soldering | Origin | China |

Product Specifications

| Category | Alloy composition(WT%) | Melting point(℃) | Application |

| Sn/Pb | Sn63Pb37 | 183 | Suitable for high requirements of circuit boards, such as: high precision instruments, electronic industry, communication, micro technology and other products welding. |

| Sn60Pb40 | |||

| Sn55Pb45 |

Product Features

The solder joint has no collapse

High purity tin

Solder shine

Uniform solder joint

Full solder joint

Good mobility

Tinning fast

The diffusivity is good

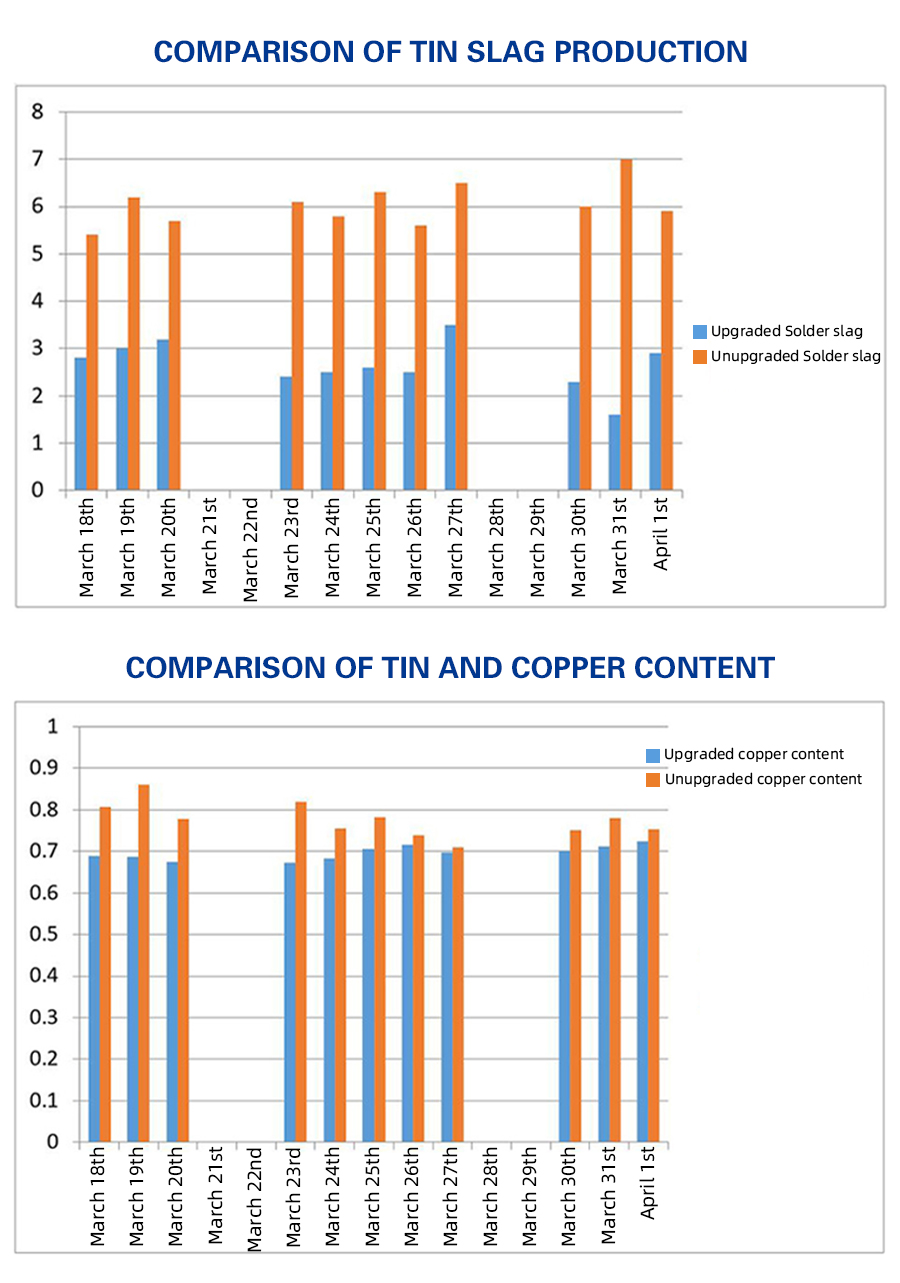

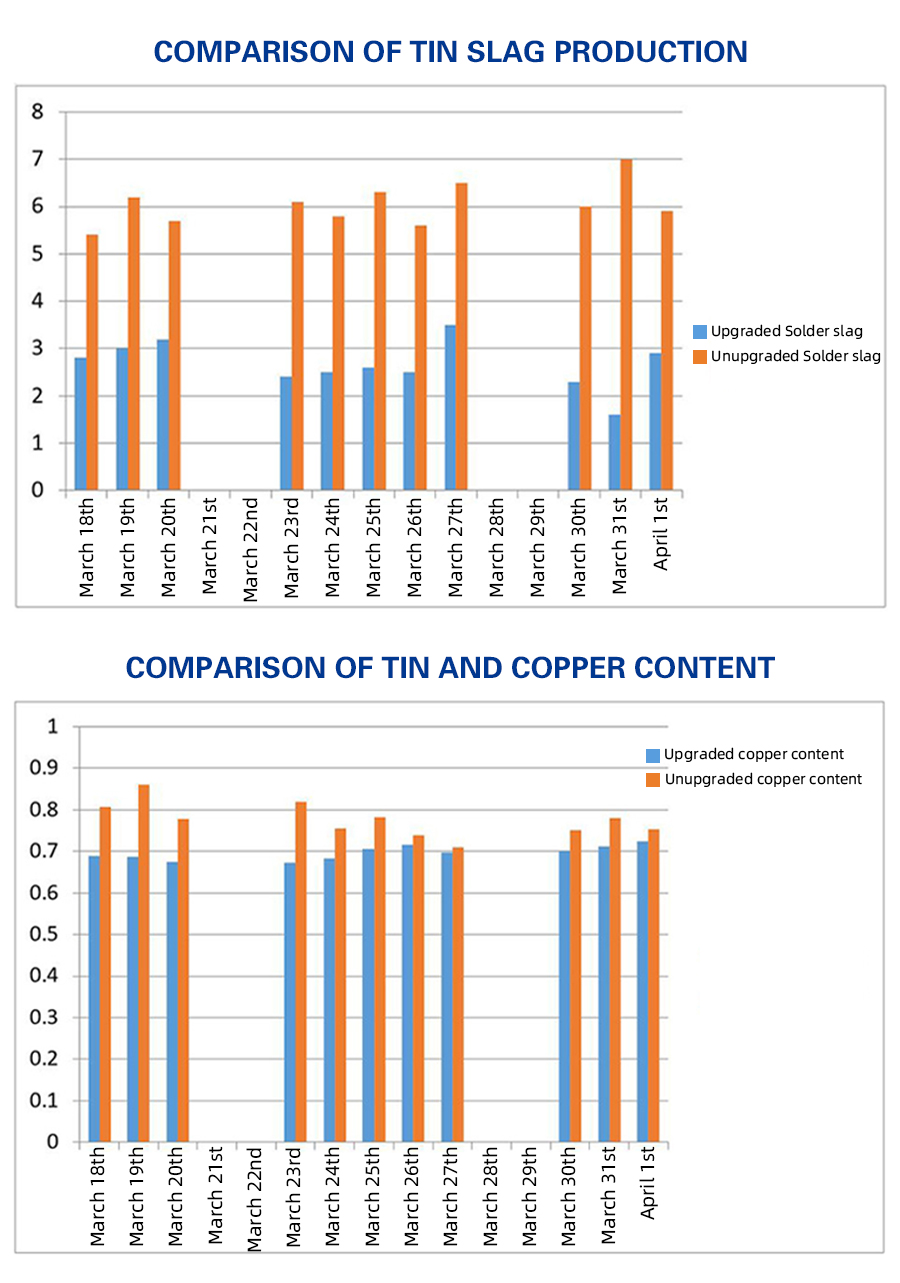

DESCRIPTION REMARKS: The above information under the samme process condiions, the operating temperature is 265℃, the chain speed is 90cm/min.the operating temperature is unchanged, the original chain speed isaccelerated from 70 cm/min to 90cm/min, from the principle analysis, the chain speed is accelerated, the fluidity of the solder has been improved, theimmersion time is short, the temperature of the tin furnace has been reduced.Therefore, working at lower temperatures has less tin slag and lower coppercarrasian!

Team Strength

Team Strength

More than 50 people production team and 13 experienced engineers and technical team.

Leading production equipment and continuous improvement of the production process.

Product Introduction

With the highest precision and efficiency, the Sn60Pb40 solder rod delivers superior performance to ensure a seamless welding experience.

Our Sn60Pb40 electrode is made of the highest quality materials and has a smooth surface. When melted, the surface of the liquid takes on a mirror-like luster.

One of the outstanding features of our Sn60Pb40 solder bars is their excellent fluidity and excellent wettability. This ensures easy application and impeccable adhesion, allowing for seamless welded connections.

During usage, the solder strip produces minimal slag, has excellent flowability, and exhibits good wetting properties, resulting in highly reliable solder joints. It remains bright and intact without any collapses, making it suitable for high-quality wave soldering in various applications. It can also be used for selective wave soldering and manual dip furnace welding.

Basic Info.

Product name | 60a Lead solder bar | Brand | singway |

Model NO. | 6040 | Material | Sn60Pb40 |

Shape | bar | Melting Point | 183±2℃ |

Individual strip weight | About 0.72kg/ piece | Packaging | 20kg/box |

| Product use | All kinds of wave soldering | Origin | China |

Product Specifications

| Category | Alloy composition(WT%) | Melting point(℃) | Application |

| Sn/Pb | Sn63Pb37 | 183 | Suitable for high requirements of circuit boards, such as: high precision instruments, electronic industry, communication, micro technology and other products welding. |

| Sn60Pb40 | |||

| Sn55Pb45 |

Product Features

The solder joint has no collapse

High purity tin

Solder shine

Uniform solder joint

Full solder joint

Good mobility

Tinning fast

The diffusivity is good

DESCRIPTION REMARKS: The above information under the samme process condiions, the operating temperature is 265℃, the chain speed is 90cm/min.the operating temperature is unchanged, the original chain speed isaccelerated from 70 cm/min to 90cm/min, from the principle analysis, the chain speed is accelerated, the fluidity of the solder has been improved, theimmersion time is short, the temperature of the tin furnace has been reduced.Therefore, working at lower temperatures has less tin slag and lower coppercarrasian!

Team Strength

Team Strength

More than 50 people production team and 13 experienced engineers and technical team.

Leading production equipment and continuous improvement of the production process.

Low-temperature lead-free solder wires have emerged as a game-changer in the manufacturing industry, especially for acoustic products. These innovative solder wires offer several benefits that make them an ideal choice for various applications. In this article, we will explore the advantages of usin

Power plug terminal soldering is a critical process in the manufacturing of electronic devices. To ensure a reliable and long-lasting connection, it is crucial to use the right solder wire. Nickel-plated lead-free solder wire has emerged as an ideal choice for this application due to its numerous be

Lead-free solder bars have emerged as a crucial solution for meeting the evolving demands of the power and automotive industries. With the increasing concern over the harmful effects of lead, these solder bars offer numerous advantages in terms of environmental sustainability, regulatory compliance,

In the rapidly evolving world of electronics, the hazards associated with lead have become a growing concern. With increased awareness of the negative effects of lead on human health and the environment, manufacturers are seeking alternative materials that provide the same level of performance witho

Stainless Steel Solder Wires for Welding Stainless Steel Tubes: A Comprehensive GuideWelding stainless steel tubes requires precision and expertise to ensure the integrity and durability of the final product. One crucial aspect of this process is choosing the right solder wires. In this article, we

When it comes to quality tin plating and soldering, choosing the right solder bar manufacturer is crucial. The selection process, however, can be overwhelming with so many options available. In this article, we will discuss the factors to consider when choosing a solder bar manufacturer and the key