| Availability: | |

|---|---|

| Quantity: | |

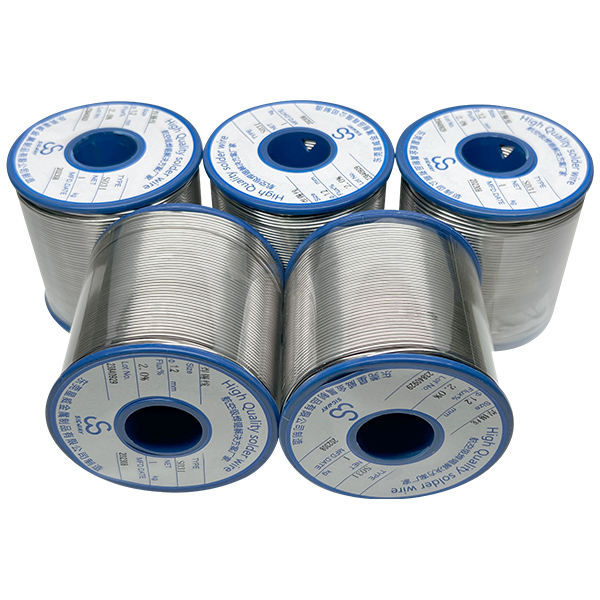

Product Introduction

Tin-lead solder wire alloy is based on the ratio of Sn20%Pb80%, using high-purity Yunnan tin gold raw materials, and through a series of strict quality control measures and process optimization, with the following outstanding characteristics to meet various welding process needs:

First, high-purity raw materials: the use of high-purity Yunnan sikgold raw materials to ensure the quality of the starting material of the alloy, reduce the impurity content, and improve the reliability and stability of the welding connection.

First, high-purity raw materials: the use of high-purity Yunnan sikgold raw materials to ensure the quality of the starting material of the alloy, reduce the impurity content, and improve the reliability and stability of the welding connection.

Second, the advantages of low-temperature welding: because the alloy composition contains a higher proportion of lead, it is suitable for low-temperature welding needs. This makes it advantageous in the welding of temperature-sensitive components and electronic devices, reducing thermal stress.

Third, high temperature stability: the base components of the alloy have been carefully designed to ensure excellent stability and oxidation resistance in high temperature environments, thus suitable for high temperature welding applications.

Fourth, reliability and consistency: through strict quality control and testing processes, to ensure that the production of welding wire alloys have a high degree of consistent performance, to provide reliable welding connections.

Fifth, customer customization: According to the specific needs of customers, the alloy formula can be further adjusted to meet the requirements of different welding processes and specific applications.

Sixth, environmental awareness: consider environmental factors in the production process, adopt green manufacturing technology, reduce waste generation, and comply with relevant environmental regulations and standards.

Basic Info.

product name | 2080 Lead solder wire | brand | singway |

Model NO. | 2080 | Material | Sn20Pb80 |

Melting Point | 183±2℃ | flux | 1.5%-4.0% |

Specific gravity | 10.16±0.1g/cm3 | Diameter of the line | 0.4-4.0MM |

Shape | filiform | Single Volume Heavy | 200 g/roll,customizable |

Packaging | 10 rolls/case | Carton Packaging | 33.8*16*6cm |

Product use | Electrical and electronic welding | Origin | China |

Product Specifications

| Solder wire specification | Type of solder wire | ||||

Ingredient (WT%) | Flux-cored solder wire | Solid core solder wire | Wash free solder wire | Three-and five-core porous solder wire | |

Sn40Pb60 | √ | √ | √ | √ | √ |

| Sn35Pb65 | √ | √ | √ | √ | √ |

| Sn30Pb70 | √ | √ | √ | √ | √ |

| Sn25Pb75 | √ | √ | √ | √ | √ |

Sn20Pb80 | √ | √ | √ | √ | √ |

Product Advantage

Product specification

Applicable to the industry

The Singway range of soldering wires is perfect for both automatic soldering machines and manual soldering irons, meeting the highest quality standards. These wires find extensive applications in industries such as wire and cable, unmanned aircraft, aerospace, communication, power manufacturing, new energy manufacturing, automotive, lighting, high-precision electronic device manufacturing, 3C product manufacturing, and other electronic technology manufacturing sectors.

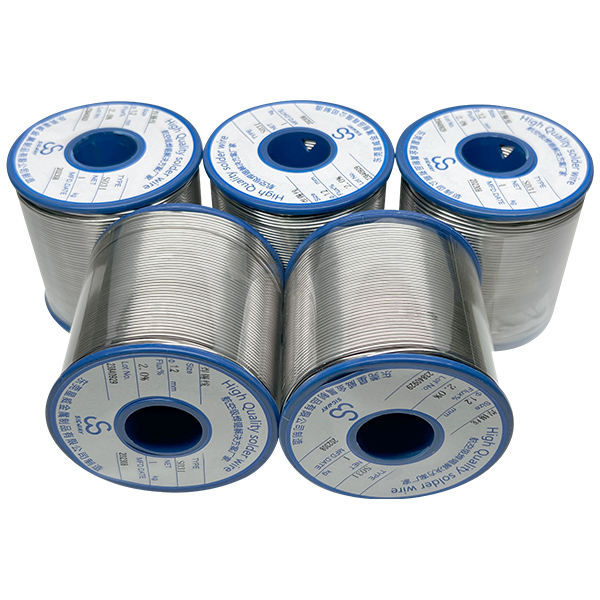

Product Introduction

Tin-lead solder wire alloy is based on the ratio of Sn20%Pb80%, using high-purity Yunnan tin gold raw materials, and through a series of strict quality control measures and process optimization, with the following outstanding characteristics to meet various welding process needs:

First, high-purity raw materials: the use of high-purity Yunnan sikgold raw materials to ensure the quality of the starting material of the alloy, reduce the impurity content, and improve the reliability and stability of the welding connection.

First, high-purity raw materials: the use of high-purity Yunnan sikgold raw materials to ensure the quality of the starting material of the alloy, reduce the impurity content, and improve the reliability and stability of the welding connection.

Second, the advantages of low-temperature welding: because the alloy composition contains a higher proportion of lead, it is suitable for low-temperature welding needs. This makes it advantageous in the welding of temperature-sensitive components and electronic devices, reducing thermal stress.

Third, high temperature stability: the base components of the alloy have been carefully designed to ensure excellent stability and oxidation resistance in high temperature environments, thus suitable for high temperature welding applications.

Fourth, reliability and consistency: through strict quality control and testing processes, to ensure that the production of welding wire alloys have a high degree of consistent performance, to provide reliable welding connections.

Fifth, customer customization: According to the specific needs of customers, the alloy formula can be further adjusted to meet the requirements of different welding processes and specific applications.

Sixth, environmental awareness: consider environmental factors in the production process, adopt green manufacturing technology, reduce waste generation, and comply with relevant environmental regulations and standards.

Basic Info.

product name | 2080 Lead solder wire | brand | singway |

Model NO. | 2080 | Material | Sn20Pb80 |

Melting Point | 183±2℃ | flux | 1.5%-4.0% |

Specific gravity | 10.16±0.1g/cm3 | Diameter of the line | 0.4-4.0MM |

Shape | filiform | Single Volume Heavy | 200 g/roll,customizable |

Packaging | 10 rolls/case | Carton Packaging | 33.8*16*6cm |

Product use | Electrical and electronic welding | Origin | China |

Product Specifications

| Solder wire specification | Type of solder wire | ||||

Ingredient (WT%) | Flux-cored solder wire | Solid core solder wire | Wash free solder wire | Three-and five-core porous solder wire | |

Sn40Pb60 | √ | √ | √ | √ | √ |

| Sn35Pb65 | √ | √ | √ | √ | √ |

| Sn30Pb70 | √ | √ | √ | √ | √ |

| Sn25Pb75 | √ | √ | √ | √ | √ |

Sn20Pb80 | √ | √ | √ | √ | √ |

Product Advantage

Product specification

Applicable to the industry

The Singway range of soldering wires is perfect for both automatic soldering machines and manual soldering irons, meeting the highest quality standards. These wires find extensive applications in industries such as wire and cable, unmanned aircraft, aerospace, communication, power manufacturing, new energy manufacturing, automotive, lighting, high-precision electronic device manufacturing, 3C product manufacturing, and other electronic technology manufacturing sectors.

Low-temperature lead-free solder wires have emerged as a game-changer in the manufacturing industry, especially for acoustic products. These innovative solder wires offer several benefits that make them an ideal choice for various applications. In this article, we will explore the advantages of usin

Power plug terminal soldering is a critical process in the manufacturing of electronic devices. To ensure a reliable and long-lasting connection, it is crucial to use the right solder wire. Nickel-plated lead-free solder wire has emerged as an ideal choice for this application due to its numerous be

Lead-free solder bars have emerged as a crucial solution for meeting the evolving demands of the power and automotive industries. With the increasing concern over the harmful effects of lead, these solder bars offer numerous advantages in terms of environmental sustainability, regulatory compliance,

In the rapidly evolving world of electronics, the hazards associated with lead have become a growing concern. With increased awareness of the negative effects of lead on human health and the environment, manufacturers are seeking alternative materials that provide the same level of performance witho

Stainless Steel Solder Wires for Welding Stainless Steel Tubes: A Comprehensive GuideWelding stainless steel tubes requires precision and expertise to ensure the integrity and durability of the final product. One crucial aspect of this process is choosing the right solder wires. In this article, we

When it comes to quality tin plating and soldering, choosing the right solder bar manufacturer is crucial. The selection process, however, can be overwhelming with so many options available. In this article, we will discuss the factors to consider when choosing a solder bar manufacturer and the key