| Availability: | |

|---|---|

| Quantity: | |

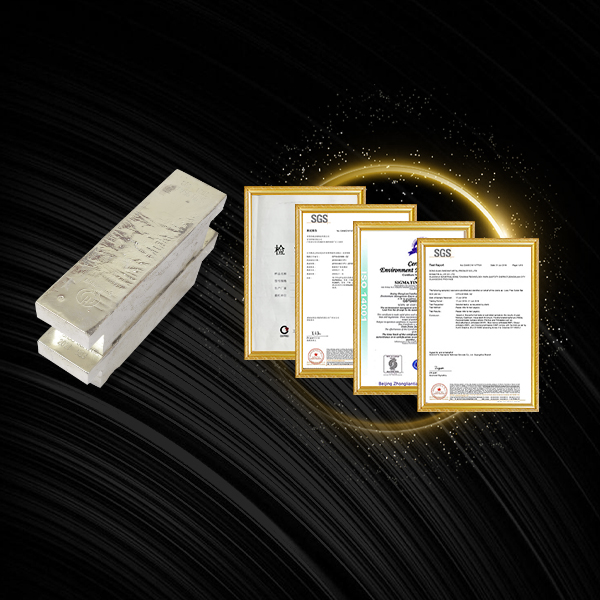

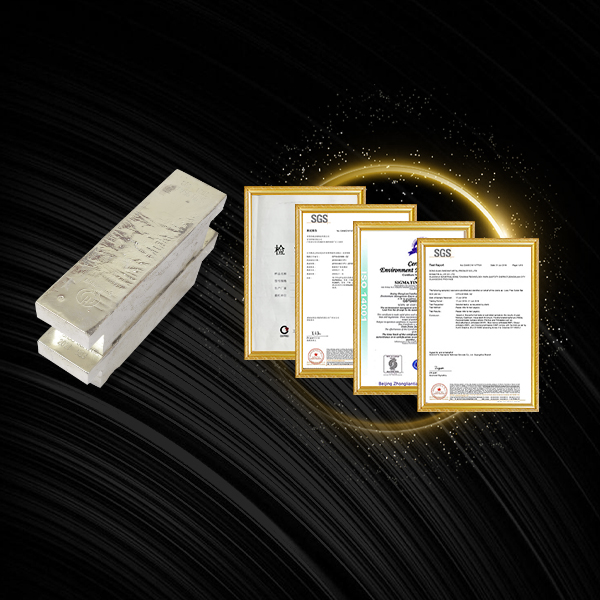

Product Introduction

Sn10 produced by Singway has lead tin strips, using pure electrolytic tin as raw material, and contains sufficient tin. The solder bar has good wettability and expansibility, solid welding, no virtual welding.

1. Sufficient tin content: SN10 has a high tin content of lead tin, ensuring that enough solder is provided during the welding process, so that the welding point is firm and reliable.

2. Good wettability and expansibility: SN10 lead tin strip has good wettability and can quickly contact and expand with welding materials to form uniform welding points.

3. Solid welding: SN10 has lead tin strips to form solid welding, and there is no gap between the welding point and the welding material, providing a more reliable connection.

4. No virtual welding: SN10 has lead tin strip welding process will not appear virtual welding phenomenon, that is, the solder is not completely wet the surface of the welding material and formed by the weak connection.

The solder strip has a sleek and shiny surface, which becomes as reflective as a mirror when it melts.

During usage, the solder strip produces minimal slag, has excellent flowability, and exhibits good wetting properties, resulting in highly reliable solder joints. It remains bright and intact without any collapses, making it suitable for high-quality wave soldering in various applications. It can also be used for selective wave soldering and manual dip furnace welding.

Basic Info.

product name | 1090 Lead solder bar | brand | singway |

Model NO. | 1090 | Material | Sn10Pb90 |

Shape | strip | Melting Point | 183℃ |

Individual strip weight | About 0.72kg/ piece | Packing | 20kg/box |

| Range of application | wave soldering machine | Origin | China |

Product Specifications

Product Features

Electrolytic pure tin

Tin-ash low

Oxidation resistance

Solder shine

Full solder joint

Low residue

Tinning fast

High reliability

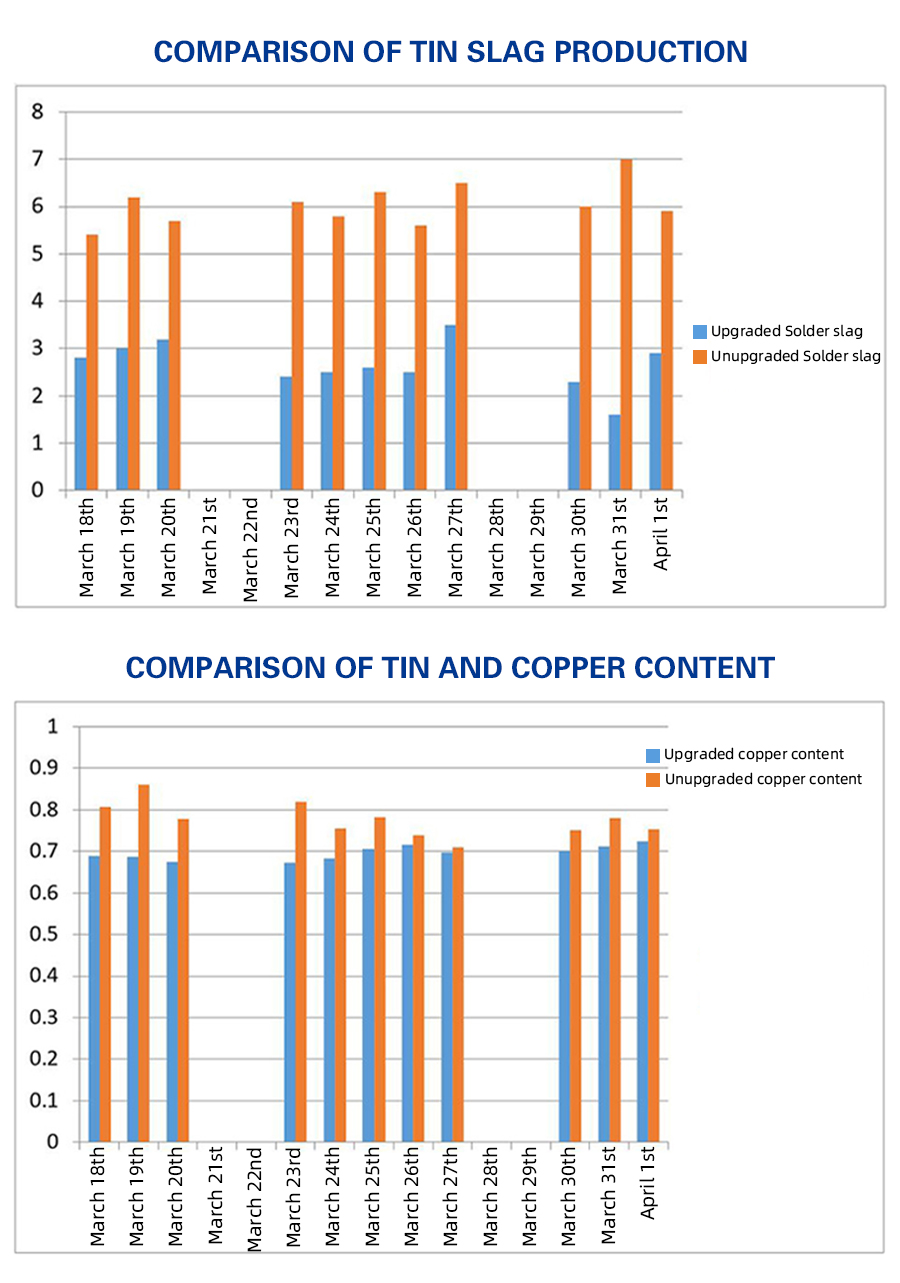

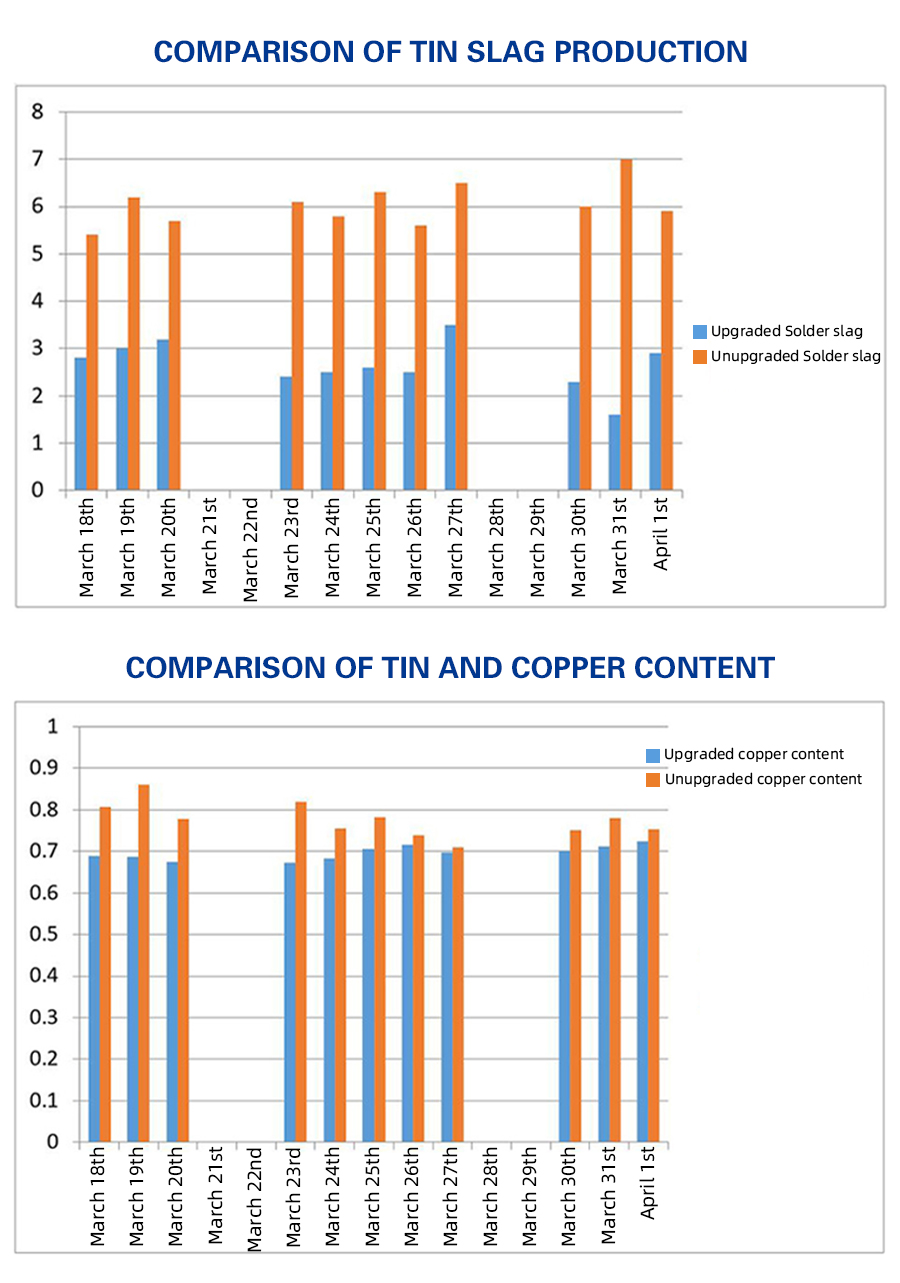

The chain speed was increased from 70cm/min to 90cm/min, a change that brought multiple benefits. First, the fluidity of the solder is significantly improved, which helps to moisten the solder joints more evenly and improve the welding quality. Second, the residence time of the solder on the welding surface is reduced, reducing the risk of oxidation and ensuring the reliability of the solder joint. At the same time, the increased fluidity of the solder allows for operation at relatively low tin furnace temperatures, reducing the likelihood of tin slag formation and making the welding environment cleaner. In addition, due to the shortened welding time, the production efficiency is improved, the energy consumption and material loss are reduced, and the production cost is reduced. Overall, increasing the chain speed has brought many aspects of optimization to the welding process, improving the quality, efficiency and economy.

Product Advantage

Raw material preparation

Using high quality and high purity tin ingot raw material + electrolytic lead fusion special process refined, less oxidation slag, good electrical and thermal conductivity, tin loading speed.

Fine process and good reliability

Low melting point, good activity, high insulation impedance, fast welding speed to reduce the thermal shock caused by welding components, while reducing the welding time of operators, improve production efficiency.

High purity tin ash less, anti-oxidation

The material is electrolysed from new high purity tin ore with sufficient degree and smooth surface.

Service Capability

Service Capability

Product Introduction

Sn10 produced by Singway has lead tin strips, using pure electrolytic tin as raw material, and contains sufficient tin. The solder bar has good wettability and expansibility, solid welding, no virtual welding.

1. Sufficient tin content: SN10 has a high tin content of lead tin, ensuring that enough solder is provided during the welding process, so that the welding point is firm and reliable.

2. Good wettability and expansibility: SN10 lead tin strip has good wettability and can quickly contact and expand with welding materials to form uniform welding points.

3. Solid welding: SN10 has lead tin strips to form solid welding, and there is no gap between the welding point and the welding material, providing a more reliable connection.

4. No virtual welding: SN10 has lead tin strip welding process will not appear virtual welding phenomenon, that is, the solder is not completely wet the surface of the welding material and formed by the weak connection.

The solder strip has a sleek and shiny surface, which becomes as reflective as a mirror when it melts.

During usage, the solder strip produces minimal slag, has excellent flowability, and exhibits good wetting properties, resulting in highly reliable solder joints. It remains bright and intact without any collapses, making it suitable for high-quality wave soldering in various applications. It can also be used for selective wave soldering and manual dip furnace welding.

Basic Info.

product name | 1090 Lead solder bar | brand | singway |

Model NO. | 1090 | Material | Sn10Pb90 |

Shape | strip | Melting Point | 183℃ |

Individual strip weight | About 0.72kg/ piece | Packing | 20kg/box |

| Range of application | wave soldering machine | Origin | China |

Product Specifications

Product Features

Electrolytic pure tin

Tin-ash low

Oxidation resistance

Solder shine

Full solder joint

Low residue

Tinning fast

High reliability

The chain speed was increased from 70cm/min to 90cm/min, a change that brought multiple benefits. First, the fluidity of the solder is significantly improved, which helps to moisten the solder joints more evenly and improve the welding quality. Second, the residence time of the solder on the welding surface is reduced, reducing the risk of oxidation and ensuring the reliability of the solder joint. At the same time, the increased fluidity of the solder allows for operation at relatively low tin furnace temperatures, reducing the likelihood of tin slag formation and making the welding environment cleaner. In addition, due to the shortened welding time, the production efficiency is improved, the energy consumption and material loss are reduced, and the production cost is reduced. Overall, increasing the chain speed has brought many aspects of optimization to the welding process, improving the quality, efficiency and economy.

Product Advantage

Raw material preparation

Using high quality and high purity tin ingot raw material + electrolytic lead fusion special process refined, less oxidation slag, good electrical and thermal conductivity, tin loading speed.

Fine process and good reliability

Low melting point, good activity, high insulation impedance, fast welding speed to reduce the thermal shock caused by welding components, while reducing the welding time of operators, improve production efficiency.

High purity tin ash less, anti-oxidation

The material is electrolysed from new high purity tin ore with sufficient degree and smooth surface.

Service Capability

Service Capability

Low-temperature lead-free solder wires have emerged as a game-changer in the manufacturing industry, especially for acoustic products. These innovative solder wires offer several benefits that make them an ideal choice for various applications. In this article, we will explore the advantages of usin

Power plug terminal soldering is a critical process in the manufacturing of electronic devices. To ensure a reliable and long-lasting connection, it is crucial to use the right solder wire. Nickel-plated lead-free solder wire has emerged as an ideal choice for this application due to its numerous be

Lead-free solder bars have emerged as a crucial solution for meeting the evolving demands of the power and automotive industries. With the increasing concern over the harmful effects of lead, these solder bars offer numerous advantages in terms of environmental sustainability, regulatory compliance,

In the rapidly evolving world of electronics, the hazards associated with lead have become a growing concern. With increased awareness of the negative effects of lead on human health and the environment, manufacturers are seeking alternative materials that provide the same level of performance witho

Stainless Steel Solder Wires for Welding Stainless Steel Tubes: A Comprehensive GuideWelding stainless steel tubes requires precision and expertise to ensure the integrity and durability of the final product. One crucial aspect of this process is choosing the right solder wires. In this article, we

When it comes to quality tin plating and soldering, choosing the right solder bar manufacturer is crucial. The selection process, however, can be overwhelming with so many options available. In this article, we will discuss the factors to consider when choosing a solder bar manufacturer and the key